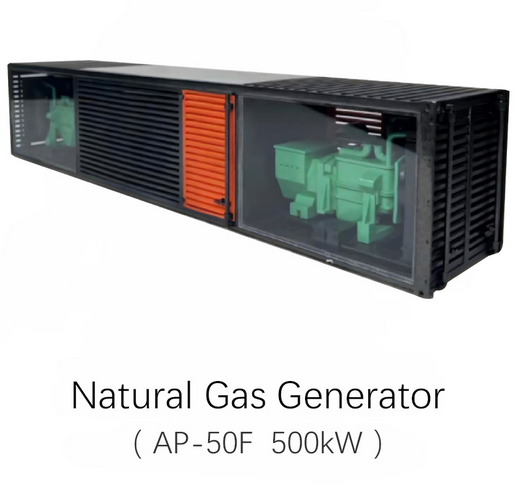

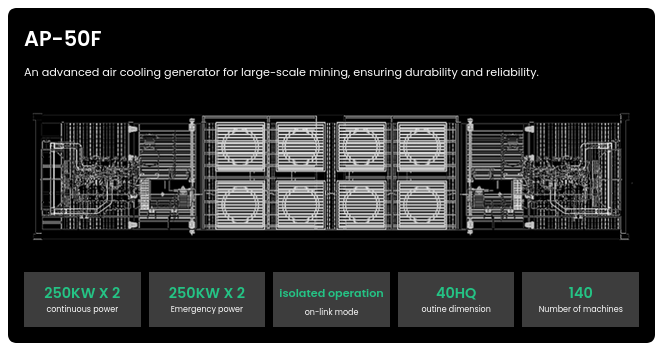

Natural Gas Generator Solution AP-50F for Air-Cooling Mining Systems Support Customization

$125,000.00

- Natural Gas Generator Solution AP-50F

- Manufacturer Warranty

Trusted By

AP-50F 500kW Solution: AP-25 250kW*2+140-Unit Air Cooling Container Package

Enhance your mining efficiency with our advanced natural gas generator solution, featuring the dual AP-25 250kW generator sets—paired with a 140-unit air-cooled mining container. This integrated system is designed to deliver reliable power and efficient cooling for large-scale mining farms.

This package provides a sustainable and scalable solution, perfect for maximizing efficiency and reducing operating costs.

Key Features

1. AP-50F 500kW Solution: Fueled by natural gas, offering a cost-effective, eco-friendly power source with consistent performance.

2. 140-Unit Air-Cooled Container: Engineered for high-capacity mining, featuring advanced air-cooling technology to ensure stable temperatures and protect your equipment.

3. Plug-and-Play Design: Simplifies setup and minimizes downtime, allowing you to scale operations seamlessly.

4. Durability & Mobility: Rugged construction with easy transport capabilities, ideal for remote or rapidly expanding mining sites.

Specifications

1. AP-50F Solution

| Size | 12192*2438*2896(L*W*Hmm,±5mm) |

| Rack | 14 Rows and 10 Columns Per Group |

| Input Voltage | Three-phase 380-480V 50/60Hz |

| Continuous Power | Three-phase 380-480V 50/60Hz |

| Max Power Load | 630 kW |

| Ambient Temperature | -25°C~35°C |

| Capacity | 140 units Antminers (Support Customization) |

| Network | 6*100M 24*bps Ethernet Switch |

| Cooling System | Air Cooling |

| Input Voltage | Three-phase 350-480V 50/60Hz |

| Output Voltage | Three-phase 350-480V 50/60Hz |

| Certification | ETL |

| Cooling Capacity | 550kW (-30°-45°) |

| Input Voltage | Three-phase 350-480V 50Hz/60Hz |

| Power Consumption | 0.75kW *8 |

| Noise | <105dB(A)@10m |

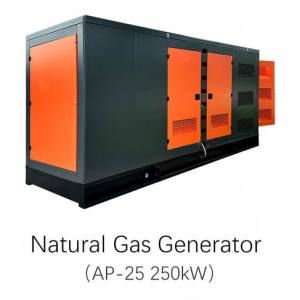

2. Generator Set

| Engine Brand | Geely |

| Engine Model | AP-25 |

| Number of Cylinders | 6 |

| Bore/Stroke | 129×165 mm |

| Displacement | 12.94 L |

| Compression Ratio | 10.5:1 |

| Rated Speed | 1500/1800 r/min |

| Intake Type | Turbocharged and Intercooled |

| Cooling Method | Closed-loop forced water cooling |

| Lubrication Method | Pressurized and splash lubrication |

| Oil Pressure | 2.5 bar–5.8 bar |

| Oil Temperature | ≤105°C |

| Oil Capacity | 32 L |

| Firing Order | 1-5-3-6-2-4 |

| Crankshaft Rotation | Counterclockwise |

| Fuel Intake Pressure | 5 kPa |

3. Engine

| Brand | Geely |

| Model | HMT13F.408 30 |

| Continuous Power | 250KW |

| Rated Current | 450A |

| Rated Frequency | 50/60Hz |

| Power Factor | 0.8 |

| Starting Method | DC 24V Electric Start |

| Speed Control Method | Electronic Speed Control |

| Fuel Control Method | Lean Burn, Closed-Loop Control |

| Ignition Method | High-Voltage Spark Plug Ignition |

| Generator Set Operation Mode | One-Key Auto Start |

| Oil Consumption Rate | ≤0.3g/kWh |

| Noise | 10 meters ≤ 101 dB(A) |

| NOx Emissions | 1.347g/kWh |

| Electrical Efficiency | 35% |

| Thermal Efficiency | 47% |

| Electrical Certification | ETL |

| Generator Set Dimensions | 3100X1330X1590mm |

| Generator Set Weight | 3140kg |

| Number of Phases and Connection Method | Three-Phase Four-Wire, Star Connection |

| Cooling Method | Pen-type Circulating Forced Water Cooling |

| Air Source Inlet Pressure | 0.4Mpa |

| Air Source Outlet Pressure | 5-10Kpa |

4. Generator

| Generator Brand | Stanford generator |

| Model | XSA4E |

| Number of Phases | Three-Phase Four-Wire |

| Insulation Class | H |

| Protection Level | IP23 |

| Excitation Method | Brushless Excitation |

| Continuous Power | 250 kW |

| Rated Speed | 1500/1800 r/min |

| Frequency | 50/60 Hz |

| Voltage | 400 V |

| Current | 450 A |

| Waveform | Sine Wave |

For most areas, the liquid cooling equipment will be shipped to you via sea freight. Ports and receiving points in different regions will incur different shipping charges. It is recommended that you contact customer service to confirm address details and calculate shipping costs before placing an order.

Related products

Power Generation

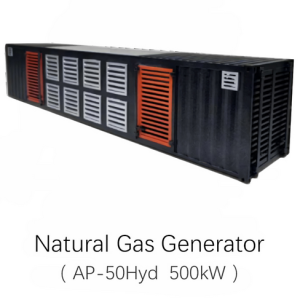

Natural Gas Generator Solution AP-50Hyd for Hydro-Cooling Mining Systems Support Customization